Our story begins in 1969, when Angelo Pessina started his own entrepreneurial venture after 15 years of experience in rubber and ebonite sector. The skills he acquired on the field allowed him to establish a facility capable of developing anti-corrosive compounds made of ebonite and rubber, and applying them to metallic products via a vulcanization process. Thus the first AP compounds were introduced: new branded products directly produced and applied in the Fara d'Adda factory.

Over the years the company has expanded and, staying true to its spirit founded on industriousness, commitment, dynamism and innovation, it has become a reliable and solid institution which can be proud that its products are exported all over the world.

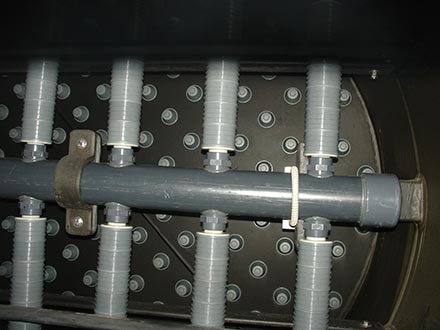

Today, in response to an increasingly demanding market, we are able to provide our customers with a 360˚ service. We not only providing expertise and realize protective treatments: we also design and produce tanks and pipes made out of polyester resin (bisphenol vinyl ester, isophthalic, etc.), including with PVC – PP – PVDF – Halar liners. We carry out the internal assembly and packaging for every destination.

Furthermore, with our internal service we carry out routine and non-routine servicing on site, revamping and testing.

In 2008 construction of the photovoltaic system was completed; with a power of 90 KW this plant provides around 20% of the energy we nowadays consume.

We have a large park for the storage of goods.

THE IMPORTANCE OF RUBBER AND EBONITE COVERINGS FOR THE PROTECTION OF METALS.

The damages caused by corrosion constitute a substantial portion of the costs that every industry faces annually. Corrosive damage is often not limited to the simple substitution of the component in question, but can entail a series of indirect damages (output losses through conductors or machinery, unplanned plant closures, loss of machinery efficiency, etc).

It is therefore important to protect the parts of the plant that are subject to this phenomenon with adequate coverings, using materials that are most suitable for the conditions of the plant.

Our AP compounds are utilized in a very wide range of applications. With responsibility and skill, we provide innovative services and products in the chemical and pharmaceutical sectors, in the field of water purification and treatment, in the gas and oil pipeline sector, as well as in the naval, food, fireproofing, agricultural, industrial coating and construction sectors.

In all cases where it is necessary to protect vital parts of plants and machinery from wear and tear, from corrosion and deterioration, our products guarantee durability and efficiency, minimising both the costs of successive maintenance as well as those from plant closure.